Here is my workshop with all the tools I will need to build my trumpet.

I have many standard home workshop tools with the notable addition of:

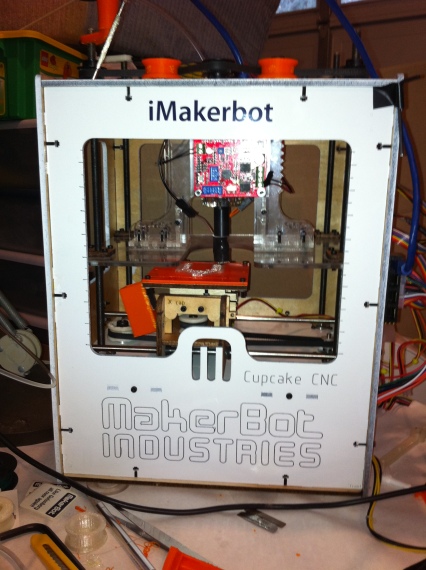

A Makerbot 3D printer (Cupcake CNC)

A Harbor Freight “precision” mini metal lathe and a HF bench grinder

A pretty nice drill press (on loan to me)

And of course the newest addition and fanciest of these tools is my CNC mini milling machine

This machine is a Little Machine Shop HiTorque Mini Mill (aka Sieg SX2). I converted it to CNC with the CNC fusion kit. My mill is a solid column mill (not very standard) so the conversion to CNC had a few hicups, but those are pretty much fixed now. I’m using the Xylotex 3-axis electronics kit with 425 oz-in stepper motors. I installed it in a storage box:

I’m currently trying to figure out a flood coolant system for this machine. So far the flood coolant has been a bit of a pain. I want to use flood because it is superior to mist and also because my air compressor cannot supply enough air (and is way too loud) to be used with mist. Flood also seemed pretty easy to setup at first, but it is proving to be more difficult than expected. The problem that seems to be really stopping me right now is the prospect for leaks. The sealant that I used seems to completely break down when you expose it to oil or coolant. It’s a clear silicone+acrylic sealant and when it is exposed to oil it turns into a white goo. I don’t want to trust my table + electronics to it. So I’ll have to remove all of that sealant and replace it with something that is resistant to chemicals and oil. Eventually I will finish this flood coolant system, but for now I’m going to just try doing things without coolant.

This machine is fairly precise and accurate. Each axis has about 3 or 4 thousandths of an inch of backlash. For a hobby machine, that’s pretty good. That’s probably within the acceptable range for my ballscrews so there’s nothing I can do about it. I’m planning on making some things that require high tolerances, so hopefully this won’t be a problem.

The thing that has been bugging me about this machine is that I can only get it to go 50 IPM (inches per minute) without skipping steps. It is a pretty smooth running machine and I’m using pretty beefy stepper motors, so this is a bit surprising, but it will probably be barely fast enough for what I want to do.